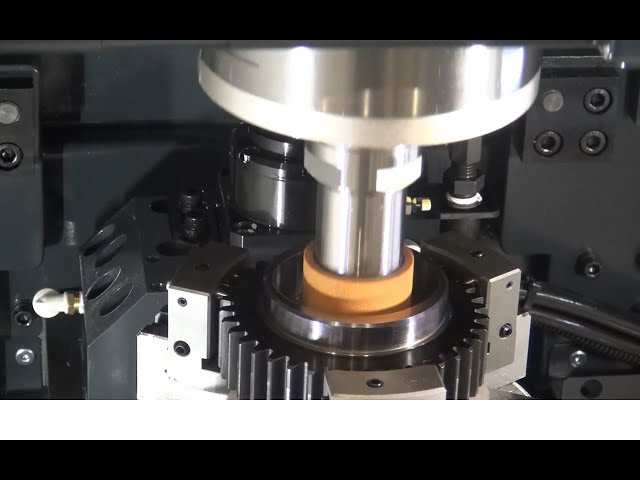

Ultra-small Vertical Grinding Machine USG-2

Exhibited in showroom

High-speed and high-accuracy grinding of non-circular workpiece

- With machine width of 29.6in, it's a compact model pursuing space saving to the max.

- Applicable for high-speed, high-accuracy grinding of non-circular workpiece. (CL-spec)

- By combining ceiling-mounted robot and workpiece stocker, productivity is increased in a compact installation area.

Specification

| Range of internal grinding diameter | ø100 mm(3.9 in) |

|---|---|

| Range of external grinding diameter | ~ ø100 mm(3.9 in) |

| Grinding length | 80 mm(3.1 in) |

| Work spindle swing | ø220 mm(8.6 in) |

| Workpiece height | 230 mm(9.0 in) [including fixture] |

| Max. loading weight on work table | 200 kg(440 lb) [including fixture] |

| Grinding spindle rotation speed | 45,000min-1 or 75,000min-1 |

| Floor space (W×D) | 750 mm(29.6 in) × 3480 mm(137.1 in) |

Highlights

High-speed/High-accuracy cam grinding CL-spec

This model performs grinding of non-circular workpiece like cam ring at a higher speed by having thrust of X-axis liner motor which is 2.2 times bigger than conventional models. Machine width 750 mm is achieved by having a low center of gravity and floor space is reduced by 47%. Also grinding programs are easily made from CAD/CAM by a dedicated software.

SRS (Smart Robot System) Option

SRS (Smart Robot System) with ceiling-mounted robot on the side of the machine allows to efficiently use the bottom space of the robot, which realizes space saving of installation area in automation system. Robot can be placed either side of the machine, which is flexibly adopted for various production lines. It also secures operation area in front of the machine which allows to keep the same workability as a stand-alone machine.

There are members-only contents on this page.

You can download product catalogs if you become a member.

Contact Us

For more information,

please send an inquiry here.