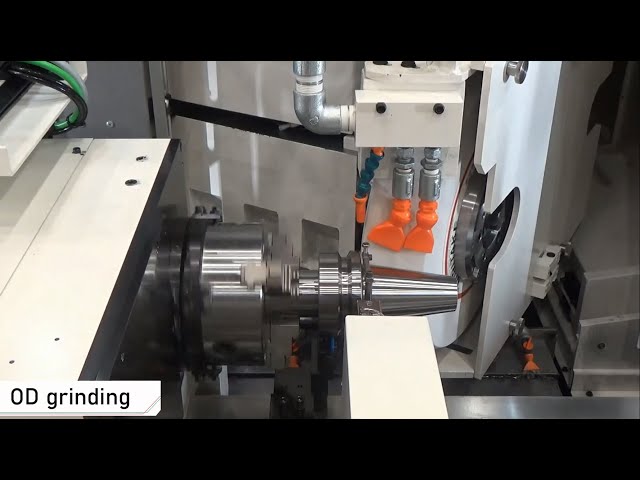

Cylindrical Multi-process Grinding Machine MGX30/160

- Multi-process model of cylindrical grinding machine -

A variety of wheelhead patterns enable process integration to achieve high-accuracy for various precision parts.

- Combination of high-accuracy grinding spindle and multi-spindle wheelhead provides high efficiency and high accuracy to machine tool parts such as spindles, tool holders, etc. to grind its shaft OD/taper/thread part/ID in one-time chucking.

- Conversational operation system equipped as standard for ease of use.

- High-accuracy taper grinding enabled by NC swivel table (OP)

Specification

| Work spindle swing | ø300 mm(11.8 in) |

|---|---|

| Distance between centers | 1,600 mm(62.9 in) |

| Supportable workpiece weight | 150 kg(330 lb) |

| Grinding wheel dimension | ø510 mm(20.0 in) × 75 mm(2.9 in) × ø203.2 mm(8.0 in) |

| Grinding spindle rotation speed | 2,700min-1 |

| Floor space (W×D) | 4,800 mm(188.9 in) × 4,200 mm(165.4 in) |

Highlights

Hydrostatic grinding spindle

High-rigidity, High-accuracy hydrostatic grinding spindle is equipped as standard.

No metallic contact allows to maintain the initial performance for a long time, and provide high rigidity and rotational accuracy from low speed to high speed.

Continuous indexing table

Direct-drive type indexing table enables continuous indexing at 0.0001° for the wheelhead.

Multi-spindle wheelhead Option

By selecting multi-spindle wheelhead, max. 3 spindles can be mounted to perform multi-processes in one-time chucking. Turret layout can be selected from 13 patterns to suit various operations in combination with continuous indexing table. Also internal grinding spindle is available as an option.

Conversational operation system

Conversational operation system with regular grinding cycles is equipped as standard with 10.4-inch touch panel employed as intuitive user interface.

There are members-only contents on this page.

You can download product catalogs if you become a member.

Contact Us

For more information,

please send an inquiry here.